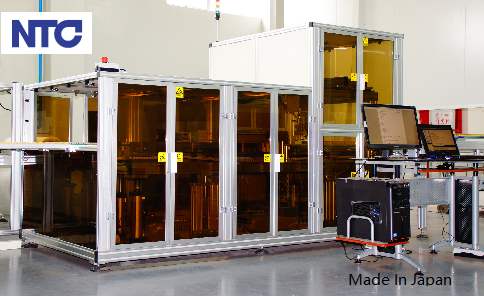

Highly automated production lines enable East Lux to supply modules with high quality, fast delivery and best LCOE

Smarter Manufacturing,Smarter Choice

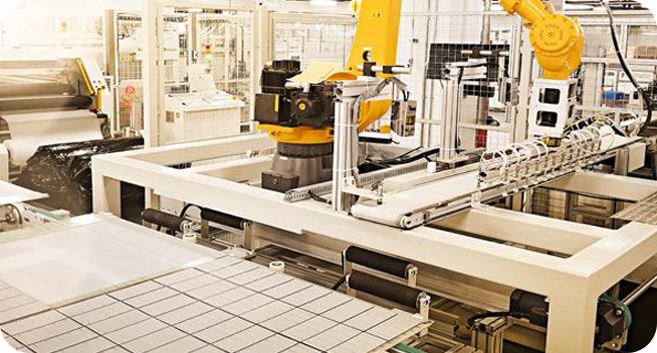

Fully Automated production Iines Enable Fast Delivery And Cost Savings

East Lux ever-improving highly automated production lines enable us to supply modules with high quality, fast delivery and low cost.

-

15%

Lower production

cost -

15%

Higher equipment

effectiveness -

24*7

Real-time online

monitoring -

100+

Patents on products and production process optimization

-

99.9%

Good product

yield rate -

35%

Higher production

efficiency

REAL-TIME Monitored And Recored

East Lux adopts strict manufacturing management and end-to-end quality control. With the help of the internally developed ERP system, we can track every

The production steps of each module component from quality control of incoming materials to online production, OBA testing and delivery status.

The ERP system implements a unique barcode for each component of the module. Information such as raw material suppliers, production workers,

quality testing results, and production details are all accessible online through our ERP system. This data will be kept on our server for client's

access. Our product monitoring system allows us to track and take responsibility for product quality. It also enables customers to log in via

Internet search real-time module production data. In the long run, this allows us to trace the product records in the database, thus providing

us the ability to further improve product quality.

Benefits of Smart Manufacturing

-

Simplify production process, improve production efficiency

-

Enhance product quality while dramatically reduce cost

-

Improve utilization rate of corporate resources and assets

-

Guarantee customer trust with transparent and traceable production process.

Added Value For Customer

-

Customers can access real-time production data including BOM detail, EL report, Power, etc.

-

Real-time updates of the production status, delivery specifics, etc. of your order.

-

A unique bar code enables you to track back all the information related to your order.

-

Visual access to real-time workshop floor monitor recordings via our ERP system.